Why a System — Not More Tools

Factories don’t need more tools — they need one connected system.

They need a connected, real-time system — not an ERP patch or another standalone tool.

DAFO synchronises operators, materials and workflows — so decisions are always based on live data.

No more silos. No more missing data.

A single system that aligns production, logistics, and people — in real time.

One flow, not disconnected apps

Operators, materials, workstations and schedules all update instantly.

Clear decisions, based on live data

From delays to material shortages — nothing stays hidden.

Full material control

Lots, batches, reservations and internal releases — fully traceable from purchase to finished goods.

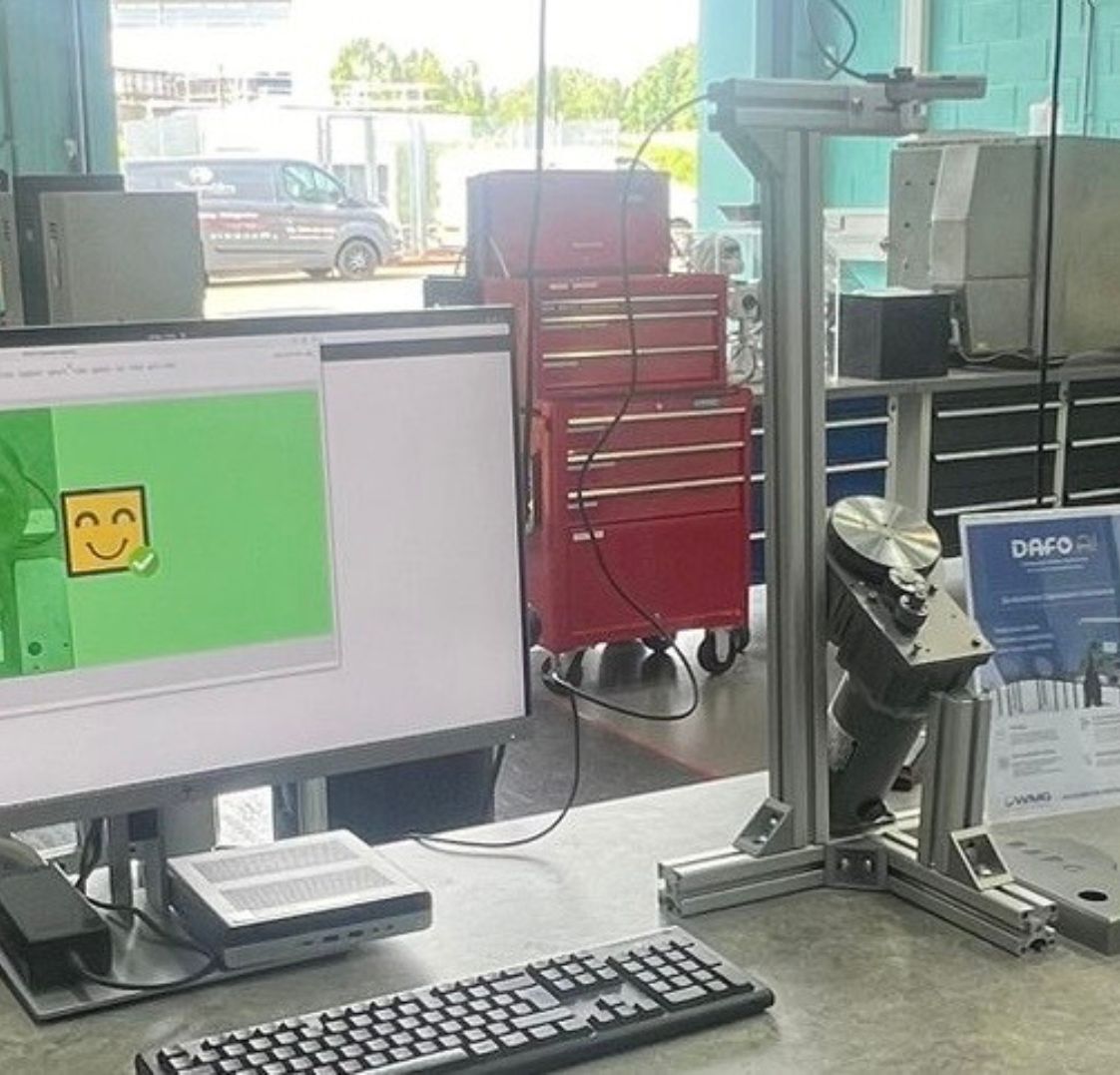

DAFO4: Think Before You Transform

DAFO4 is our strategic methodology for digital transformation.

It helps organisations align people, systems, and workflows through four interconnected dimensions:

Let’s work together